The production standards of copper pipes are given in the table below.

|

Production Standards |

|

TS EN 1057+A1 |

|

TS EN 12449+A1 |

|

TS EN 12451 |

|

TS EN 13600:2013 |

Rigid polyurethane foam is an insulation material with an extremely low thermal transmission coefficient, consisting of mixing of polyol and isocyanate in certain ratios and pressure injection of these materials. PUR, which is injected between the carrier pipe and the casing pipe (HDPE), provides heat insulation as well as enables two pipes to operate as one pipe by bonding them together and filling in the space between the pipes longitudinally. In the manufacturing of pre-insulated geothermal pipes, the PUR in accordance with the standard TS EN 253 has to meet the following minimum requirements:

Technical Specifications

|

Components |

Polyol and Isocyanate |

|

Minimum cellular mass density |

55 kg/m3 ISO 845 |

|

Max. Thermal Conductivity Coefficient |

0,029 W/mK ISO 8497 |

|

Average cell structure |

< 0,5 mm |

|

Closed cell content |

> %88 ISO 4590 |

|

Min. Radial Compressive Strength |

0,30 MPa ISO 844 |

|

Water absorption at high temperature |

< 10% when tested according to TS EN 253 5.3.5 |

|

Axial cutting strength |

23 °C ± 2 °C ≥ 0,12 N/mm² |

|

140 °C ± 2 °C ≥ 0,08 N/mm² |

|

|

Temperature range |

-50 °C / +148 °C |

|

Impact strength |

No damage must exist - when tested in accordance with EN 253 5.4.5 |

|

Linear Water Tightness |

Must be Watertight When tested in accordance with EN 253 5.4.6 |

|

Chlorofluorocarbon |

None |

|

The service life of insulation according to continuous service temperature |

3 years at 140 ˚C |

|

30 years at 120 ˚C |

|

|

50 years at 115 ˚C |

Extruded polyethylene casing pipe is used on the outermost part, which protects the insulation material from external factors and chemicals. The HDPE casing pipe manufactured in accordance with the standards TS EN 253 and TS EN 12201-2 must contain antioxidants, UV stabilisers and carbon black.

Technical Specifications

|

Standard |

EN 253, EN 12201-2 |

|

Dimensions |

EN 253 part 4.3.2.2 table5 |

|

Material |

PE 80 – PE 100 ISO 9080 |

|

Density |

> 944 kg/m3 ISO 1133 |

|

Thermal Conductivity Coefficient |

0,43 W/mK |

|

Thermal Stability (OIT) |

> 20 min (210 °C) ISO 11357-6 |

|

Temperature Range |

40 °C / + 80 °C |

|

Cracking resistance under stress |

> 300 hrs (4 MPa, 80 °C) ISO 16770 |

|

Post-thermal treatment changes |

<%3 no damage must exist) ISO 2505 |

|

Melt Flow Index (MFI 190°C/5kg) |

0,2 < MFR ≤ 1,0 g/10dk ISO 1133 |

|

Carbon black content |

> by mass 2.5% ± 0.5 ISO 6964 |

|

Carbon black propagation degree |

<3 ISO 18553 |

|

Breaking elongation |

>% 350 ISO 6259-1 |

|

Hydrostatic Strength |

10,8 bar 80°C 165 sa ISO 1167-1-2 |

|

Inner surface treatment |

Corona process on extruded line (on-line) |

|

UV Protection |

Yes |

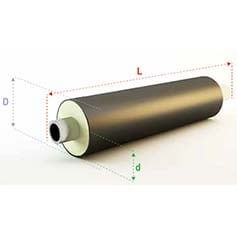

| PRODUCT NOMINAL SIZE | COPPER PIPE | HDPE CASING PIPE | PUR | PIPE LENGTH | INSULATED PIPE WEIGHT(kg/m) | ||||||

| DN | INCH | Outer Diameter dₐ (mm) | Wall Thickness t (mm) | kg/m | Outer Diameter D (mm) | Wall Thickness (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | ||

| Ø 20/90 | 20 | 3/4" | 20 | 1,50 | 0,78 | 90 | 3,0 | 84,0 | 32 | 6 | 1,97 |

| Ø 25/90 | 25 | 1" | 25 | 1,50 | 0,99 | 90 | 3,0 | 84,0 | 29,5 | 6 | 2,17 |

| Ø 30/110 | 32 | 1 1/4" | 35 | 1,50 | 1,41 | 110 | 3,0 | 104,0 | 34,5 | 6 | 2,96 |

| Ø 40/110 | 40 | 1 1/2" | 42 | 2,20 | 2,45 | 110 | 3,0 | 104,0 | 31 | 6 | 3,98 |

| Ø 50/125 | 50 | 2" | 54 | 3,70 | 5,20 | 125 | 3,0 | 119,0 | 32,5 | 6 | 7,00 |

| Ø 65/140 | 65 | 2 1/2" | 64 | 4,40 | 7,33 | 140 | 3,0 | 134,0 | 35 | 6 | 9,42 |

| Ø 80/160 | 80 | 3" | 80 | 2,30 | 5,00 | 160 | 3,0 | 154,0 | 37 | 6 | 7,47 |

| Ø 100/200 | 100 | 4" | 105 | 2,50 | 7,17 | 200 | 3,2 | 193,6 | 44,3 | 6 | 10,71 |

| Ø 100/200 | 100 | 4" | 108 | 4,50 | 13,02 | 200 | 3,2 | 193,6 | 42,8 | 6 | 16,52 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

- Copper pipe outer diameters, wall thicknesses and unit weights may vary depending on the request.

What is Pre-Insulated (Geothermal) Copper Pipe?

Pre-insulated copper pipes are insulated pipes obtained by insulating copper pipes with rigid polyurethane foam and are used safely in many installation projects.

After the insulation process, geothermal copper pipes gain resistance against external factors as well as their insulation properties. The diameters and lengths of copper pipes produced by Yalçın Boru are given in the table above. Apart from the diameters and lengths specified in the table, insulation is also made for copper pipes prepared upon request.

How to Produce Pre-Insulated Copper Pipes?

Pre-insulated copper pipes are obtained by coating a mixture of polyol and isocyanate between copper pipes produced in various diameters and features and HDPE sheath pipe. After this process, which we call PUR insulation, copper pipes gain excellent thermal insulation.

In addition, the geothermal HDPE sheath pipe of Yalçın Boru pre-insulated copper pipes has antioxidant properties and contains UV stabilizers and carbon black. Geothermal copper pipes can be produced in the desired wall thickness.

Pre-insulated copper pipes complete the production process by going through very special processes. After production, both the copper pipe and the insulation layer undergo certain tests. Products that pass these tests prove that they have superior quality and high durability.

Advantages of Pre-Insulated Copper Pipes

The advantages of pre-insulated copper pipes, which are formed by the combination of the insulation layer and copper pipes, are as follows:

Provides high thermal insulation: The temperature of the fluid is kept as stable as possible during hot or cold fluid transfer.

Provides energy savings: High energy savings are achieved in heating and cooling systems as the fluid heat is preserved at the maximum level.

Ease of use: Since copper can be shaped easily, its application is simple.

Easy to install: Both copper pipe and insulation material are easy to process.

Provides superior protection against external factors: These external factors include moisture, chemicals, physical impacts and sunlight. Pre-insulated pipes are extremely durable against all these factors.

High fire resistance: The insulation layer of copper pipes provides fire resistance.

It is environmentally friendly: Thanks to pre-insulation, the lifespan of copper pipes increases and it is environmentally friendly since it is recyclable.

Maintenance cost is low: Copper pipes are protected from external factors by insulation, thus reducing maintenance requirements.

What are the Usage Areas of Pre-Insulated Copper Pipes?

The usage areas of pre-insulated copper pipes, which have high durability and energy efficiency, are as follows:

- Air conditioning systems

- Heating and cooling installations

- Installations of various industrial establishments

- Medical gas installations

- Natural gas and LPG installations

- Transportation installations of petroleum and derivative products

- Plumbing systems

Things to Consider When Selection of Pre-Insulated Copper Pipes

It is very important to choose pre-insulated copper pipes, which have a wide range of uses, to suit the projects.

- First of all, you should choose the appropriate diameter insulated copper pipe for your project.

- You should be careful to use insulation material that is suitable for hot or cold fluid temperatures.

- The installation process must be carried out in a way that preserves the insulation properties of copper pipes.

- You can use a pre-insulated pipe jointing set for assembly.

You can also find out whether geothermal copper pipes, which offer various advantages, are suitable for your project by contacting us.