The manufacturing quality and manufacturing standards of PPR-C pipes are given in the table. PPR-C pipes are manufactured in PN10, PN16 and PN20 pressure categories in general..

|

Production Standards |

|

TS 9937 |

|

TS EN ISO 15874-2 |

|

TS 11755-4 |

|

DIN 8077 |

|

DIN 8078 |

Rigid polyurethane foam is an insulation material with extremely low thermal transmission coefficient, consisting of mixing of polyol and isocyanate in certain ratios and pressure injection of these materials. PUR, which is injected between the carrier pipe and the casing pipe (HDPE), provides heat insulation as well as enabling two pipes operating as one pipe by bonding them together, and filling in the space between the pipes longitudinally. In the manufacturing of pre-insulated pipes, the PUR in accordance with the standard TS EN 253 has to meet the following minimum requirements:

Technical Specifications

|

Components |

Polyol and Isocyanate |

|

Minimum cellular mass density |

55 kg/m3 ISO 845 |

|

Max. Thermal Conductivity Coefficient |

0,029 W/mK ISO 8497 |

|

Average cell structure |

< 0,5 mm |

|

Closed cell content |

> %88 ISO 4590 |

|

Min. Radial Compressive Strength |

0,30 MPa ISO 844 |

|

Water absorption at high temperature |

< 10% when tested according to TS EN 253 5.3.5 |

|

Axial cutting strength |

23 °C ± 2 °C ≥ 0,12 N/mm² |

|

140 °C ± 2 °C ≥ 0,08 N/mm² |

|

|

Temperature range |

-50 °C / +148 °C |

|

Impact strength |

No damage must exist - when tested in accordance with EN 253 5.4.5 |

|

Linear Water Tightness |

Must be Watertight When tested in accordance with EN 253 5.4.6 |

|

Chlorofluorocarbon |

None |

|

Service life of insulation according to continuous service temperature |

3 years at 140 ˚C |

|

30 years at 120 ˚C |

|

|

50 years at 115 ˚C |

Extruded polyethylene casing pipe is used on the outermost part, which protects the insulation material from external factors and chemicals. The HDPE casing pipe manufactured in accordance with the standards TS EN 253 and TS EN 12201-2 must contain antioxidants, UV stabilisers and carbon black.

Technical Specifications

|

Standart |

EN 253, EN 12201-2 |

|

Dimensions |

EN 253 section 4.3.2.2.2 table 5 |

|

Material |

PE 80 – PE 100 ISO 9080 |

|

Density |

> 944 kg/m3 ISO 1133 |

|

Thermal Conductivity Coefficient |

0,43 W/mK |

|

Thermal Stability (OIT) |

> 20 min (210 °C) ISO 11357-6 |

|

Temperature Range |

40 °C / + 80 °C |

|

Cracking resistance in tension |

> 300 Hours (4 MPa, 80 °C) ISO 16770 |

|

Changes after heat treatment |

<3% (no damage) ISO 2505 |

|

Melt Flow Index (MFI 190°C/5kg) |

0,2 < MFR ≤ 1,0 g/10dk ISO 1133 |

|

Carbon black content |

> 2.5 ± 0.5 % by mass ISO 6964 |

|

Carbon black propagation degree |

<3 ISO 18553 |

|

Breaking elongation |

>% 350 ISO 6259-1 |

|

Hydrostatic Strength |

10,8 bar 80°C 165 sa ISO 1167-1-2 |

|

Inner surface treatment |

Corona treatment on the extruded line (on-line) |

|

UV Protection |

Yes |

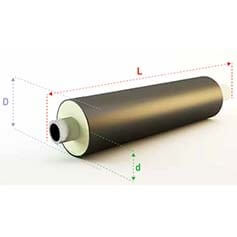

| PRODUCT NOMINAL SIZE | PPR-C PIPE**** | HDPE CASING PIPE | PUR | PIPE LENGTH | |||

| DN | Outer Diameter dₐ (mm) | Outer DiameterD (mm) | Wall Thicknesss (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | |

| Ø 20/75 | 20 | 20 | 75 | 3,0 | 69,0 | 24,5 | 4 |

| Ø 25/90 | 25 | 25 | 90 | 3,0 | 84,0 | 29,5 | 4 |

| Ø 32/90 | 32 | 32 | 90 | 3,0 | 84,0 | 26 | 4 |

| Ø 40/110 | 40 | 40 | 110 | 3,0 | 104,0 | 32 | 4 |

| Ø 50/110 | 50 | 50 | 110 | 3,0 | 104,0 | 27 | 4 |

| Ø 63/125 | 63 | 63 | 125 | 3,0 | 119,0 | 28 | 4 |

| Ø75/140 | 75 | 75 | 140 | 3,0 | 134,0 | 29,5 | 4 |

| Ø 90/160 | 90 | 90 | 160 | 3,0 | 154,0 | 32 | 4 - 6 - 12 |

| Ø 110/200 | 110 | 110 | 200 | 3,2 | 193,6 | 41,8 | 4 - 6 - 12 |

| Ø 125/225 | 125 | 125 | 225 | 3,4 | 218,2 | 46,6 | 4 - 6 - 12 |

| Ø 160/250 | 160 | 160 | 250 | 3,6 | 242,8 | 41,4 | 4 - 6 - 12 |

| Ø 200/280 | 200 | 200 | 280 | 3,9 | 272,2 | 36,1 | 4 - 6 - 12 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm.

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

- The wall thickness of PPR-C carrier pipes may vary depending on the desired SDR category.

PRE-INSULATED PPR-C PIPES - GEOTHERMAL PIPES

GEOTHERMAL PIPE SYSTEMS MADE OF POLYPROPYLENE (PP PIPES)

If you are considering using advanced engineered polymer geothermal pipes instead of metal pipe systems in your new project, you need to pay attention to many different points. Especially the selection, planning and installation stages are very important.

It has become important to use polypropylene in the manufacture of pipe systems due to its technically and environmentally friendly properties. Polypropylene material, which has been used for many years, is a reliable product by practitioners with many advantages.

WHAT ARE THE APPLICATION AREAS OF POLYPROPYLENE GEOTHERMAL PIPE SYSTEMS?

Polypropylene geothermal pipes are resistant to high levels of chemical resistance. It has stability between 0°C-80°C temperature values. Again, this type of pipes have high pressure resistance and also act as a good insulator.

Some of the numerous application areas of PP pipes are as follows:

- Drinking water transport pipes

- Heating and ventilation installations

- Air conditioning pipe systems

- District or localized heating and cooling networks

- Pipes to be laid for cooling systems

- Surface cooling and heating systems

- Sprinkler systems

- Chemical transport pipes

- Renewable energy lines

- Pipework systems required for maritime navigation

ADVANTAGES OF POLYPROPYLENE PIPE SYSTEMS

- Engineered polypropylene pipes are lighter than metal pipes.

- While metal pipes are susceptible to corrosion, polymer pipes are resistant to corrosion.

- Polypropylene pipes can be recycled while metal pipes cannot be recycled.

- Engineered polymer pipes are more durable than metal pipes.

- In general, polypropylene pipes are resistant to many chemicals.

- Polymer plastic pipes have high abrasion resistance.

- There is no open flame operation during the application of plastic polypropylene pipes.

- Polymer plastic pipes are cheaper due to the low cost of raw materials.

WHAT IS PLASTIC PIPE - PPRC?

Polypropylene random copolymer pipes, also known as plastic pipes in the industry, PPR-C is translated into Turkish as Polypropylene Random Copolymer. PPRC pipe is light and smooth. The inner surfaces of PPRC pipes are shiny. Pipes that are suitable in terms of hygiene have taken their place in the plastic pipe industry with advantages such as easy installation feature. Compared to galvanised pipes, it has been a good solution for carrying hot water in indoor applications. This type of plastic pipes used in both hot and cold water systems in buildings are of high quality in terms of raw materials.

The raw material of polypropylene random copolymer (PPRC) material is of 3 types. These types are divided into classes in terms of heat, pressure and chemical resistance. These raw material classes;

- Type-1, raw material PP-H (polypropylene homopolymer),

- Type-2, raw material PP-B (polypropylene blockcopolymer),

- Type-3, raw material PP-RC (Polypropylene Randomkopolymer),

- Type-4, raw material PP-RCT (Crystallinity Modified Polypropylene Random Copolymer)

which are raw materials.

The performance of the materials whose raw material is Polypropylene Random Copolymer (PP-R) and the materials whose raw material is Polypropylene Random Copolymer with modified crystallinity is higher in terms of both physical and chemical properties compared to Type-1 and Type-2. Their properties are also better than others.

WHAT ARE THE USAGE AREAS OF PPRC PIPES?

Considering the general properties of these raw materials; the main use of pipes produced using polypropylene is in systems where hot and cold fluids are transported. Plastic pipes used in industrial pipe installations due to their resistance to chemicals can be used safely in compressed air systems due to the same feature. PPRC pipe systems show high resistance to heat and the hazards posed by chemicals. It is used in facilities required for cold and hot water transport. PP-R, which has a monomer structure, does not allow harmful biological substances due to this feature while forming a random chain. PPRC pipes can be coloured. It does not cause any change in the taste and odour of the fluid transported through the pipe. It has a 50-year service life at ideal pressures and temperature values.

Main Features of PPRC Systems;

1. 20 °C and 25 atm pressure, 50 years service life.

2. Suitable for use between 20°C and +95°C (the freezing point of the fluid in the pipe insulation should be taken into account).

3. Durable for these reasons.

4. High resistance to chemical substances.

5. The inner surface is slippery and shiny.

6. The color, smell and taste of water do not change.

7. Provides heat and sound insulation.

8. No bending occurs in the diameters of the welding parts. This provides the highest performance in welding.

9. Up to 70% savings can be achieved in assembly and installation.

10. It is also environmentally friendly.

WHY ARE PPR-C GEOTHERMAL PIPES PREFERRED?

- It has an ideal structure that can withstand temperatures between 4°C- 95°C.

- The pipe does not show calcification and rusting and is also resistant to corrosion.

- Since it is lighter than other pipes, it is simple and easy to transport and install.

- This convenience provides savings close to 70%.

- PPRC geothermal pipes, which have a hygienic structure, do not affect the colour, taste and smell of the transported water.

- Friction coefficient of Polypropylene Random Copolymer pipes is also low.

- Pipe welding process is easy. Socket fusion welding can be used for joining.

- There is no diameter narrowing with the welding process.

- PPRC geothermal pipes are resistant to chemical substances. They have high resistance.

- In general, the service life is minimum 50 years when the instructions for use and the recommendations of the manufacturers are followed.

- PPRC pipes do not harm the environment.

- The inner surface part has a slippery and shiny appearance.