Pre-Insulated (Heat Insulated - Geothermal) Steel Pipes - Production - Advantages - Application Areas

The steel pipes used in the manufacturing of pre-insulated pipes have the following features as longitudinally welded (ERW) or spirally welded (SAW) in accordance with the norms required by the standard TS EN 253 or customer demands.

Technical Specifications

|

PRODUCTION STANDARDS |

QUALITY OF STEEL |

|

TS EN 10217-1 |

P195TR1-TR2, P235TR1-TR2, P265TR1-TR2 |

|

TS EN 10217-2 |

P195GH TC1, P235GH TC1, P265 GH TC1 |

|

TS EN 10255+A1 |

S195T |

|

TS EN 10217-3 |

P355 N, P355 NH |

|

TS EN 10217-5 |

P235GH TC1, P265 GH TC1 |

|

TS EN 10219-1 |

S235JR, S275JR |

|

ASTM A53 |

Grade A, Grade B |

|

API 5L (PSL1 - PSL2) |

Grade A, Grade B, X42, X52, X56, X60, X65, X70, X80 |

|

DIN 1626 |

St.37, St.44, St.52 |

|

DIN 2440 |

St.33 |

|

Manufacturing Range |

½” (Ø15) – 48” (Ø1200) |

|

Dimensions and Weight |

DIN 2448 / EN 10220 |

|

Certification |

TS EN / 10204 3.1.B |

|

Welding Groove |

DIN 2559/22, ISO 6761 |

|

Surface Quality |

Steel granule sanding process can be carried out in the standards of EN ISO 8501-1 SA 2 1/2 |

|

Lengths |

6 m, 12 m, 16 m |

Rigid polyurethane foam is an insulation material with extremely low thermal transmission coefficient, consisting of mixing of polyol and isocyanate in certain ratios and pressure injection of these materials. PUR, which is injected between the carrier pipe and the casing pipe (HDPE), provides heat insulation as well as enabling two pipes operating as one pipe by bonding them together, and filling in the space between the pipes longitudinally. In the manufacturing of pre-insulated pipes, the PUR in accordance with the standard TS EN 253 has to meet the following minimum requirements:

|

Components |

Polyol and Isocyanate |

|---|---|

|

Minimum cellular mass density |

55 kg/m3 ISO 845 |

|

Max. Thermal Conductivity Coefficient |

0,029 W/mK ISO 8497 |

|

Average cell structure |

< 0,5 mm |

|

Closed cell content |

> %88 ISO 4590 |

|

Min. Radial Compressive Strength |

0,30 MPa ISO 844 |

|

Water absorption at high temperature |

< % 10, TS EN 253 5.3.5’ e göre test edildiğinde |

|

Axial cutting strength |

23 °C ± 2 °C ≥ 0,12 N/mm² |

|

140 °C ± 2 °C ≥ 0,08 N/mm² |

|

|

Temperature range |

-50 °C / +148 °C |

|

Impact strength |

No damage must exist - when tested in accordance with EN 253 5.4.5 |

|

Linear Water Tightness |

Must be Watertight When tested in accordance with EN 253 5.4.6 |

|

Chlorofluorocarbon |

None |

|

Service life of insulation according to continuous service temperature |

3 years at 140 ˚C |

|

30 years at 120 ˚C |

|

|

50 years at 115 ˚C |

Extruded polyethylene casing pipe is used on the outermost part, which protects the insulation material from external factors and chemicals. The HDPE casing pipe manufactured in accordance with the standards TS EN 253 and TS EN 12201-2 must contain antioxidants, UV stabilisers and carbon black.

|

Standard |

EN 253, EN 12201-2 |

|---|---|

|

Dimensions |

EN 253 bölüm 4.3.2.2 tablo 5 |

|

Material |

PE 80 – PE 100 ISO 9080 |

|

Density |

> 944 kg/m3 ISO 1133 |

|

Thermal Conductivity Coefficient |

0,43 W/mK |

|

Thermal Stability (OIT) |

> 20 min (210 °C) ISO 11357-6 |

|

Temperature Range |

40 °C / + 80 °C |

|

Cracking resistance under stress |

> 300 Saat (4 MPa, 80 °C) ISO 16770 |

|

Post-thermal treatment changes |

<%3 (hasar olmamalı) ISO 2505 |

|

Melt Flow Index (MFI 190°C/5kg) |

0,2 < MFR ≤ 1,0 g/10dk ISO 1133 |

|

Carbon black content |

> Kütlece % 2,5 ± 0,5 ISO 6964 |

|

Carbon black propagation degree |

<3 ISO 18553 |

|

Breaking elongation |

>% 350 ISO 6259-1 |

|

Hydrostatic Strength |

10,8 bar 80°C 165 sa ISO 1167-1-2 |

|

Inner surface treatment |

Corona process on extruded line (on-line) |

|

UV Protection |

Yes |

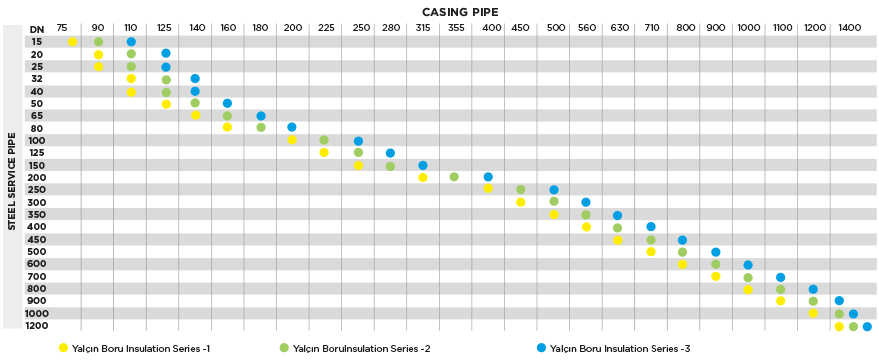

| PRODUCT NOMINAL SIZE | STEEL PIPE | HDPE CASING PIPE | PUR | PIPE LENGTH | INSULATED PIPE WEIGHT (kg/m) | |||||

| DN | INCH | Outer Diameter dₐ (mm) | Wall Thickness t (mm) | Outer Diameter D (mm) | Wall Thickness s (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | ||

| Ø 15/75 | 15 | 1/2" | 21,3 | 2,00 | 75 | 3,0 | 69,0 | 23,85 | 6 | 1,87 |

| Ø 20/90 | 20 | 3/4" | 26,9 | 2,00 | 90 | 3,0 | 84,0 | 28,55 | 6 | 2,41 |

| Ø 25/90 | 25 | 1" | 33,7 | 2,30 | 90 | 3,0 | 84,0 | 25,15 | 6 | 2,93 |

| Ø 32/110 | 32 | 1 1/4" | 42,4 | 2,60 | 110 | 3,0 | 104,0 | 30,8 | 6 | 4,07 |

| Ø 40/110 | 40 | 1 1/2" | 48,3 | 2,60 | 110 | 3,0 | 104,0 | 27,85 | 6 | 4,42 |

| Ø 50/125 | 50 | 2" | 60,3 | 2,90 | 125 | 3,0 | 119,0 | 29,35 | 6 | 5,85 |

| Ø 65/140 | 65 | 2 1/2" | 76,1 | 2,90 | 140 | 3,0 | 134,0 | 28,95 | 6 | 7,22 |

| Ø 80/160 | 80 | 3" | 88,9 | 3,20 | 160 | 3,0 | 154,0 | 32,55 | 6 | 9,15 |

| Ø 100/200 | 100 | 4" | 114,3 | 3,60 | 200 | 3,2 | 193,6 | 39,65 | 6 | 13,25 |

| Ø 125/225 | 125 | 5" | 139,7 | 3,60 | 225 | 3,4 | 218,2 | 39,25 | 6-12 | 16,12 |

| Ø 150/250 | 150 | 6" | 168,3 | 4,00 | 250 | 3,6 | 242,8 | 37,25 | 6-12 | 20,82 |

| Ø 200/315 | 200 | 8" | 219,1 | 4,50 | 315 | 4,1 | 306,8 | 43,85 | 6-12 | 30,54 |

| Ø 250/400 | 250 | 10" | 273 | 5,00 | 400 | 4,8 | 390,4 | 58,7 | 6-12 | 43,56 |

| Ø 300/450 | 300 | 12" | 323,9 | 5,60 | 450 | 5,2 | 439,6 | 57,85 | 6-12 | 56,38 |

| Ø 350/500 | 350 | 14" | 355,6 | 5,60 | 500 | 5,6 | 488,8 | 66,6 | 6-12 | 63,64 |

| Ø 400/560 | 400 | 16" | 406,4 | 6,30 | 560 | 6,0 | 548,0 | 70,8 | 6-12 | 80,81 |

| Ø 450/630 | 450 | 18" | 457 | 6,30 | 630 | 6,6 | 616,8 | 79,9 | 6-12 | 93,29 |

| Ø 500/710 | 500 | 20" | 508 | 6,30 | 710 | 7,2 | 695,6 | 93,8 | 6-12 | 107,44 |

| Ø 600/800 | 600 | 24" | 610 | 7,10 | 800 | 7,9 | 784,2 | 87,1 | 6-12 | 139,82 |

| Ø 700/900 | 700 | 28" | 711 | 8,00 | 900 | 8,7 | 882,6 | 85,8 | 6-12 | 179,40 |

| Ø 800/1000 | 800 | 32" | 812,8 | 8,80 | 1000 | 9,4 | 981,2 | 84,2 | 6-12 | 221,55 |

| Ø 900/1100 | 900 | 36" | 914 | 10,00 | 1100 | 10,2 | 1079,6 | 82,8 | 6-12 | 277,47 |

| Ø 1000/1200 | 1000 | 40" | 1016 | 10,50 | 1200 | 11,0 | 1178,0 | 81 | 6-12 | 322,27 |

| Ø 1200/1400 | 1200 | 48" | 1219 | 12,50 | 1400 | 12,5 | 1375,0 | 78 | 6-12 | 449,90 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm.

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

| PRODUCT NOMINAL SIZE | STEEL PIPE | HDPE CASING PIPE | PUR | PIPE LENGTH | INSULATED PIPE WEIGHT (kg/m) | |||||

| DN | INCH | Outer Diameter dₐ (mm) | Wall Thicknesst (mm) | Outer Diameter D (mm) | Wall Thickness s (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | ||

| Ø 15/90 | 15 | 1/2" | 21,3 | 2,00 | 90 | 3,0 | 84,0 | 31,35 | 6 | 2,14 |

| Ø 20/110 | 20 | 3/4" | 26,9 | 2,00 | 110 | 3,0 | 104,0 | 38,55 | 6 | 2,81 |

| Ø 25/110 | 25 | 1" | 33,7 | 2,30 | 110 | 3,0 | 104,0 | 35,15 | 6 | 3,34 |

| Ø 32/125 | 32 | 1 1/4" | 42,4 | 2,60 | 125 | 3,0 | 119,0 | 38,3 | 6 | 4,41 |

| Ø 40/125 | 40 | 1 1/2" | 48,3 | 2,60 | 125 | 3,0 | 119,0 | 35,35 | 6 | 4,76 |

| Ø 50/140 | 50 | 2" | 60,3 | 2,90 | 140 | 3,0 | 134,0 | 36,85 | 6 | 6,22 |

| Ø 65/160 | 65 | 2 1/2" | 76,1 | 2,90 | 160 | 3,0 | 154,0 | 38,95 | 6 | 7,74 |

| Ø 80/180 | 80 | 3" | 88,9 | 3,20 | 180 | 3,0 | 174,0 | 42,55 | 6 | 9,72 |

| Ø 100/225 | 100 | 4" | 114,3 | 3,60 | 225 | 3,4 | 218,2 | 51,95 | 6 | 14,22 |

| Ø 125/250 | 125 | 5" | 139,7 | 3,60 | 250 | 3,6 | 242,8 | 51,55 | 6-12 | 17,19 |

| Ø 150/280 | 150 | 6" | 168,3 | 4,00 | 280 | 3,9 | 272,2 | 51,95 | 6-12 | 22,29 |

| Ø 200/355 | 200 | 8" | 219,1 | 4,50 | 355 | 4,5 | 346,0 | 63,45 | 6-12 | 32,97 |

| Ø 250/450 | 250 | 10" | 273 | 5,00 | 450 | 5,2 | 439,6 | 83,3 | 6-12 | 47,24 |

| Ø 300/500 | 300 | 12" | 323,9 | 5,60 | 500 | 5,6 | 488,8 | 82,45 | 6-12 | 60,47 |

| Ø 350/560 | 350 | 14" | 355,6 | 5,60 | 560 | 6,0 | 548,0 | 96,2 | 6-12 | 68,96 |

| Ø 400/630 | 400 | 16" | 406,4 | 6,30 | 630 | 6,6 | 616,8 | 105,2 | 6-12 | 87,96 |

| Ø 450/710 | 450 | 18" | 457 | 6,30 | 710 | 7,2 | 695,6 | 119,3 | 6-12 | 102,29 |

| Ø 500/800 | 500 | 20" | 508 | 6,30 | 800 | 7,9 | 784,2 | 138,1 | 6-12 | 118,84 |

| Ø 600/900 | 600 | 24" | 610 | 7,10 | 900 | 8,7 | 882,6 | 136,3 | 6-12 | 154,07 |

| Ø 700/1000 | 700 | 28" | 711 | 8,00 | 1000 | 9,4 | 981,2 | 135,1 | 6-12 | 195,02 |

| Ø 800/1100 | 800 | 32" | 812,8 | 8,80 | 1100 | 10,2 | 1079,6 | 133,4 | 6-12 | 239,04 |

| Ø 900/1200 | 900 | 36" | 914 | 10,00 | 1200 | 11,0 | 1178,0 | 132 | 6-12 | 296,59 |

| Ø 1000/1400 | 1000 | 40" | 1016 | 10,50 | 1400 | 12,5 | 1375,0 | 179,5 | 6-12 | 365,02 |

| Ø 1200/1400 | 1200 | 48" | 1219 | 12,50 | 1400 | 12,5 | 1375,0 | 78 | 6-12 | 449,90 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm.

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

| PRODUCT NOMINAL SIZE | STEEL PIPE | HDPE CASING PIPE | PUR | PIPE LENGTH | INSULATED PIPE WEIGHT (kg/m) | |||||

| DN | INCH | Outer Diameter dₐ (mm) | Wall Thickness t (mm) | Outer Diameter D (mm) | Wall Thickness s (mm) | Inner Diameter (mm) | Thickness (mm) | L (mt) | ||

| Ø 15/110 | 15 | 1/2" | 21,3 | 2,00 | 110 | 3,0 | 104,0 | 41,35 | 6 | 2,55 |

| Ø 20/125 | 20 | 3/4" | 26,9 | 2,00 | 125 | 3,0 | 119,0 | 46,05 | 6 | 3,14 |

| Ø 25/125 | 25 | 1" | 33,7 | 2,30 | 125 | 3,0 | 119,0 | 42,65 | 6 | 3,67 |

| Ø 32/140 | 32 | 1 1/4" | 42,4 | 2,60 | 140 | 3,0 | 134,0 | 45,8 | 6 | 4,77 |

| Ø 40/140 | 40 | 1 1/2" | 48,3 | 2,60 | 140 | 3,0 | 134,0 | 42,85 | 6 | 5,12 |

| Ø 50/160 | 50 | 2" | 60,3 | 2,90 | 160 | 3,0 | 154,0 | 46,85 | 6 | 6,74 |

| Ø 65/180 | 65 | 2 1/2" | 76,1 | 2,90 | 180 | 3,0 | 174,0 | 48,95 | 6 | 8,31 |

| Ø 80/200 | 80 | 3" | 88,9 | 3,20 | 200 | 3,2 | 193,6 | 52,35 | 6 | 10,45 |

| Ø 100/250 | 100 | 4" | 114,3 | 3,60 | 250 | 3,6 | 242,8 | 64,25 | 6 | 15,30 |

| Ø 125/280 | 125 | 5" | 139,7 | 3,60 | 280 | 3,9 | 272,2 | 66,25 | 6-12 | 18,66 |

| Ø 150/315 | 150 | 6" | 168,3 | 4,00 | 315 | 4,1 | 306,8 | 69,25 | 6-12 | 24,07 |

| Ø 200/400 | 200 | 8" | 219,1 | 4,50 | 400 | 4,8 | 390,4 | 85,65 | 6-12 | 35,87 |

| Ø 250/500 | 250 | 10" | 273 | 5,00 | 500 | 5,6 | 488,8 | 107,9 | 6-12 | 51,33 |

| Ø 300/560 | 300 | 12" | 323,9 | 5,60 | 560 | 6,0 | 548,0 | 112,05 | 6-12 | 65,79 |

| Ø 350/630 | 350 | 14" | 355,6 | 5,60 | 630 | 6,6 | 616,8 | 130,6 | 6-12 | 76,11 |

| Ø 400/710 | 400 | 16" | 406,4 | 6,30 | 710 | 7,2 | 695,6 | 144,6 | 6-12 | 96,95 |

| Ø 450/800 | 450 | 18" | 457 | 6,30 | 800 | 7,9 | 784,2 | 163,6 | 6-12 | 113,69 |

| Ø 500/900 | 500 | 20" | 508 | 6,30 | 900 | 8,7 | 882,6 | 187,3 | 6-12 | 133,10 |

| Ø 600/1000 | 600 | 24" | 610 | 7,10 | 1000 | 9,4 | 981,2 | 185,6 | 6-12 | 169,69 |

| Ø 700/1100 | 700 | 28" | 711 | 8,00 | 1100 | 10,2 | 1079,6 | 184,3 | 6-12 | 212,51 |

| Ø 800/1200 | 800 | 32" | 812,8 | 8,80 | 1200 | 11,0 | 1178,0 | 182,6 | 6-12 | 258,16 |

| Ø 900/1400 | 900 | 36" | 914 | 10,00 | 1400 | 12,5 | 1375,0 | 230,5 | 6-12 | 339,34 |

| Ø 1000/1400 | 1000 | 40" | 1016 | 10,50 | 1400 | 12,5 | 1375,0 | 179,5 | 6-12 | 365,02 |

| Ø 1200/1400 | 1200 | 48" | 1219 | 12,50 | 1400 | 12,5 | 1375,0 | 78 | 6-12 | 449,90 |

- Non-insulated pipe ends will have a length of 150 - 250 mm ±10 mm.

- Upon request, manufacturing can be made in lengths, diameters and insulation thicknesses different from the values in the table.

- Our company reserves the right to make changes on this and all other data in the brochures, written documentation and on our website. You may contact our company for getting up-to-date information.

General information about the production, usage advantages, and areas of Pre-Insulated (Heat Insulated - Geothermal) Steel Pipes

Briefly, steel, steel, and iron, which have similar properties, are commonly referred to interchangeably. While iron is a metal substance, steel is an alloy formed by mixing iron with carbon and other elements by human hands. Both iron and steel have hardness and flexibility with corrosion resistance over a wide range of temperature levels and areas of extreme humidity. Steel is generally used in water, flammable gases, and fire sprinkler installations. Some of the characteristics of cast iron are that it does not crush, does not deafen, and is resistant to corrosion. Cast iron is used in plumbing, storm drain, waste, and vent piping systems. Ductile iron, lighter than cast iron material, is more robust, durable, and long-lasting. Uncoated alloy steels (Chrome-moly) are more robust than carbon steel and have properties that do not break quickly and easily. Available in uncoated black steel or malleable iron made from corrosion-resistant non-galvanized steel. The properties of zinc galvanized steel are that it is resistant to rust, corrosion, mineral deposits, and wet conditions (resistant) and consists of a zinc coating. Steel and iron geothermal pipes and geothermal pipe fittings are produced in various sizes and shapes. In this article, we will both give information about steel and talk about the usage areas of steel and the benefits of using geothermal steel pipes.

History of Steel Pipe

Mankind has used pipes for thousands of years for different needs. The first use in history was by agriculturalists who wanted to carry water from streams and rivers to their fields for irrigation. Evidence obtained from archaeological research has shown that water was moved by the Chinese to places where it was needed through reed pipes in the 2000s BC. Research has also revealed that some other ancient societies used clay pipes to transport water from one place to another. The first lead pipes on the European continent were produced in the 1st century AD. It has been in Tropical countries where bamboo pipes are used to transport water following geography. On the other hand, Colonial Americans used wood to transport water to meet their water needs. When we came 1652, the first waterworks started to be done with the help of hollow logs in the state of Boston, USA.

When we came to the 1800s, the development of modern steel pipe continued until the beginning of this year. William Murdock, who found a coal-burning lamp installation in 1815, brought together the rifle barrels that were unused and became waste to illuminate the entire city of London with the coal-burning lamps he had invented. The purpose of this system is to transport coal gas with barrel pipes. With the intelligence and work of William Murdock, the lighting system has successfully illuminated London. Thanks to this thriving business, the demand for long metal pipes has also increased. With the increase in demand for metal pipes, the supply had to grow, so many inventors started working to develop new pipe construction works.

In 1824, a patent was obtained by James Russell for an early and essential technique for mass-producing metal pipes at a low cost. In James Russell's method, pipes were formed by joining the opposite sides of a flat iron plate. The heated metal was made malleable. The edges of the iron strip are folded together and welded by means of a hammer in the hands of expert craftsmen. The pipe, made by the James Russell method, was made ready after grooving and rolling.

Although James Russell's method was used for a while, it lasted only a short time. This is because Cornelius Whitehouse developed a new method for producing metal pipes a year later. This process, discovered by Cornelius Whitehouse and defined as butt welding, is the basis of today's pipe manufacturing methods and principles. In this method, developed by Cornelius Whitehouse, thin iron sheets are heated and drawn through a cone-shaped aperture. As the metal material passes through the cone-shaped opening, its edges are bent to form a tubular shape. To complete the pipe construction process, the two ends were welded together. This method was also accepted in the United States of America, and the first facility to produce using the same method was opened in Philadelphia in 1832.

Over time, there have been developments in the Cornelius Whitehouse method, and improvements have been made in the method with the studies on it. The system introduced by John Moon in 1911 is one of the most effective of these innovations and improvements. The method introduced by John Moon is the continuous process in which a pipe production factory can produce pipes with an endless flow.

What is steel pipe?

A steel pipe is a long, hollow pipe used in many fields to meet and serve different purposes. Two other methods produce steel pipes. The result of this method is a welded or seamless pipe. In both ways, the crude steel is initially brought into a machinable form. The pipe is then formed by stretching the steel into a seamless pipe or welding the edges together. At the beginning of the 1800s, the first methods for the production of steel pipes began to be used. The pipes we use today have gained these features by constantly developing. Steel pipe manufacturing reaches millions of tons every year. Steel pipe has become one of the most frequently used products produced by the steel industry due to its versatility and use in many areas.

Steel pipes can be used in many places. Thanks to its strong structure, it is used in cities and towns for underground water and gas transportation. They are also used in construction to protect electrical wires. Another feature of steel pipes is that they are light. With this feature, it has also found a place in the bicycle frame industry. Some other uses are automobiles, cooling facilities, heating, and sanitary installations, flag poles, street lighting, and pharmaceuticals.

What are the advantages of using steel pipe?

Using steel pipes in many areas, such as residential or industrial projects, has multiple advantages. Steel pipe has been used very popularly both in the world and throughout the country today. Many companies and contractors in the construction industry prefer steel pipes over other materials. While there are many reasons why steel pipe is the most preferred pipe used in countless projects, it has five main advantages over other materials. These advantages are:

Durability and Robustness

Steel pipes are more robust and durable than pipes made of other materials. Apart from its other benefits, its strength and durability make steel pipes a preferred product for users. The strength of the steel tube makes it resistant to vibrations, shock and high pressure. While other metals can break under overload, steel, in contrast, prevents spills or leaks as it bends without breaking even under extreme stresses.

Stainlessness

While other metals corrode easily for different reasons, steel pipes, on the contrary, do not corrode easily and are not subject to deterioration (corrosion). Steel pipes resist the chemical reactions that cause them. For this reason, steel pipes are easy to maintain. It lasts longer than other pipes and tubes.

Ease of Assembly and Installation

Steel pipes of any height, width and strength can be manufactured with the qualities to meet the needs of companies dealing with unique works. Steel pipes, which are easy to install, can also be easily changed in the areas where they are used. All kinds of maintenance of the assembled steel pipe system can be done easily and quickly. This is because steel is an easy metal to machine.

High Capacity Compared to Others

Steel pipes, which are stronger than many other types of metal pipes, can be manufactured in much larger sizes and thinness without affecting their durability and quality and creating a negative situation in those properties. Thanks to these superior aspects, both its cost is reduced, and it can be adapted to individuals' special needs and budgets.

Features that do not harm the environment and nature

It may be hard to believe with the use of steel pipes, but environmentally and nature-friendly applications can be made perfectly. An average of 70% of the steel, which is preferred in applications in different parts of the world, is recycled every year. While recycling, the quality and durability of the steel are not damaged. Our company always keeps itself open to development, specializes in steel pipes, and strives to offer its customers the most durable and quality products at an affordable price.

What are the areas where steel pipes are used?

There are many different methods of using these pipes in construction sites, as well as the advantages of utilising steel pipe applications compared to other metal pipe types. The advantageous aspects of the steel pipe that we have previously explained have been a major factor in the selection of steel pipes in different applications that we will mention below. Some applications for the use of steel pipe systems in residential and industrial areas are as follows:

Transport of Domestic Water:

Since steel pipes have a structure that resists rust and corrosion, they are a great choice for water distribution networks for residential buildings. In systems where pipes are usually transported underground, steel pipes can withstand pressure, shock and vibration thanks to their strength, durability and durability.

Construction and Building Sector:

Companies serving in the construction market now prefer steel pipes for foundations and framing installations of buildings. Contractors also use steel pipes for building railings, posts, scaffolding, scaffolding, fences, chimney pipes and temporary structures.

Construction of Auxiliary Facilities:

Steel pipes are also offered as a solution for the coating of underground power lines, power lines, gas pipes, water installation systems. Since durability and robustness features are important for the protection of sensitive lines, steel pipe systems and tubes that incorporate these features have become a great choice.

Hot Water and Gas Line Facilities:

Steel pipes are also preferred for extreme systems such as hot water transport and gas transport. Black coloured steel pipes are considered to be the best solution for these types of installations due to the strength and durability of the pipe in the inner area and the iron oxide coating on the outer wall.

Sewerage:

Steel pipes, which have a structure resistant to corrosion and deterioration, are an ideal method for underground sewerage systems. The most preferred pipe type for underground sewerage systems is galvanised corrugated steel pipes. In order to cope with the very high levels of pressure regularly found in underground sewage installations, fluctuations in galvanized corrugated steel pipes are used.

What is pre-insulated - geothermal steel pipe?

Pre-insulated steel pipes(geothermal pipes) are produced by placing a special insulation layer on the surface of the steel pipelines. Thanks to this design, the heat losses of the transported hot or cold fluids are minimized. Pre-insulated steel pipes are mostly created using two components. These are steel pipe and insulation material. High-quality steel pipes ensure the safe transportation of fluids. The high-quality mineral wool, glass fiber or polyurethane material used in the insulation of the steel pipe provides insulation of the fluid in the steel pipe against hot and cold environments. High-performance insulation materials are processed on the outer surface of the steel pipe with special processes. The heat of the fluids transported by pre-insulated steel pipes is preserved for a much longer time along the line.

Pre-heat insulated steel pipes are used in the heating, cooling and ventilation systems of buildings, especially in industrial facilities. Transporting hot and cold fluids requires very high energy consumption. The use of pre-insulated steel pipes in the transport of fluids contributes to the reduction of high energy costs.

Heat losses during fluid transfer are minimized and energy savings are achieved. Pre-insulated steel pipes used in heating, cooling, ventilation and many other areas bring environmental benefits by helping to reduce carbon emissions with the energy savings they provide.

Pre-insulated(geothermal) steel pipes are produced in different diameters and lengths according to different working conditions and the characteristics of the fluids to be transported. The insulation material is produced in accordance with the standards required by the fluid to be transported and environmental conditions. The insulation material outside the steel pipes both preserves the heat of the transported fluid and acts as a protective layer against external factors. Thus, extra security against environmental conditions is provided. Pre-insulated steel pipes offer top performance in terms of high energy saving, safety and efficiency.

The structure of pre-insulated - geothermal steel pipes

All pre-insulated geothermal pipe systems for district heating, underground hot and cold distribution and many other processes have a high-quality steel carrier pipe assembly that allows the transport of high-temperature and high-pressure fluids with a total service life of up to 30 years. In addition, insulating materials with increased thickness can be used to prevent heat losses. With the help of this material, heat loss is significantly reduced. Most often this material is rigid polyurethane foam insulation blown using cyclopentane, which insulates the steel carrier pipe.

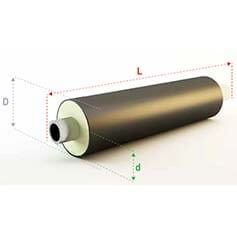

The casing (protection sheath) pipe, manufactured using high-density polyethylene material, protects the pre-insulated geothermal steel pipe from the negative effects of the external environment. The heat-insulated pipe consists of a carbon steel service (carrier) pipe, polyurethane (PUR) foam insulation and High-Density Polyethylene (HDPE) outer sheath casing.

Since the carrier pipe is very important for the system to be used, the material it is made of is also very important. When selecting the carrier pipe, the type of medium to be transported and the operating temperature values and pressures are considered. The following pipe types can be used in the carrier pipe section of the pre-insulated steel pipe.

- Spiral welded steel pipe (SAW),

- Welded pipe (ERW),

- Stainless steel pipe,

- Polyethylene pipe (HDPE100),

- Steel-drawn pipe,

- Copper pipe

- Polypropylene (PPR),

- Polypropylene Random Copolymer (PPR-C),

- Glass fibre reinforced polyester pipe (GRP),

- Glass fibre-reinforced epoxy pipe (CTE) can be used.

PE100 outer casing pipe (polyethylene) is used as a protective (casing). Its properties are commonly UV-added, black, high density, polyethylene, density > 940 kg/m3. The properties and dimensions of high-density seamless polyethylene pipes comply with TS EN 253 standards. With corona application, the sheath is not separated from the pipe and continuous connection is guaranteed by PUR Polyurethane foam material. In addition, the tensile resistance of the insulated pipe can withstand up to -50 degrees.

Which material is suitable for the protection of pre-insulated steel pipes and which material is selected accordingly is important and depends on a number of criteria. The most important criterion for this selection is the condition of the planned installation area. For example, polyethylene is generally selected for underground applications and above-ground applications where special joints are used, while zinc-coated steel material is selected for above-ground distribution systems. In addition, stainless steel or aluminum spiral wound overlapped sheets can be used for these applications. In demanding applications with more severe conditions, polyethylene-coated steel pipes can be preferred for trenchless routing.

The insulation material (PUR) is made of polyurethane. Polyurethane solid (rigid) foam contains polyol and isocyanate as components. Thermal conductivity is 0.0274 W/(mK) or 0.0275 W/(mK). Foam density is at least 60 kg/m3 according to TS EN-253 norms. Insulation material can continuously operate with the fluid at various temperatures up to 120˚C. The temperature of this fluid can reach up to 140˚C from time to time.

The heat communication (permeability) coefficient remains constant during the insulation life (minimum 30 years). Thanks to polyurethane foam insulation material, heat loss is almost negligible. Operating cost is constant during the insulation life. Installation of heat insulated steel pipes is simple. You can save time and labour by using geothermal pipe. You can minimise labour errors by using insulated steel pipes. There is no need for a gallery during the laying of the pipes, the laying process is carried out by burying directly into the soil.

In the laying process of heat-insulated pipes, elongation materials (compensators) are either not used or used at a minimum level depending on the laying technique. Since the bearings are applied on the outer protection sheath in the application processes made on the console in the gallery, thermal bridges do not occur. Steel pipe and casing pipe can be made of different materials according to the status of the project. In order to make leakage surveillance, it can be produced in productions where the appropriate monitoring wire is placed.

Technical specifications of pre-insulated (geothermal) steel pipes

Pre-insulated steel pipes fulfill all requirements of European standards (EN 253, EN 448, EN 488 and EN 489). The pipe operating parameters of the pre-insulated steel pipes produced are generally Insulation norm EN 253, Standard API 5L, ASTM A53 / A106 / A333, EN 10216-2 P235GH / P265GH, outer diameter: 21.3 - 813 mm, length: 5.8 m, 6 m, 11.8 m, 12 m, 16 m. With a 30-year service life and a maximum operating pressure of 2.5 MPa, the maximum operating temperature is 142°C. In shorter periods this temperature can be 150°C. If a pipe resistant to higher temperatures is desired, PUR foam-insulated geothermal pipes with increased thermal resistance up to 165 ° C can also be produced.

Application areas of geothermal steel pipes

Pre-insulated pipe systems produced by combining different components are widely used in the chemical and refrigeration industry, drinking water distribution networks, sewerage lines and other systems. Pre-insulated pipes that provide district heating and cooling suitable for the area and system in which they will be used are constantly being developed. The dimensions of the pipelines to be laid for district heating and cooling systems can cover very large and long areas. There are system solutions suitable for these dimensions and structure.

Pipelines for the distribution of hot water or steam in thermal systems can operate in conjunction with distant heat sources, which are more powerful and more effective in the combustion process at high temperatures than units that are not connected to a specific centre. In addition, these pipework systems are supplemented with effective filters to reduce the value of emissions.

Geothermal pipes, which are mostly used in district heating systems, are also offered as a solution for transporting excess heat generated by renewable heat sources or from power plants and industrial and agricultural production.

Other areas of usage;

- Petroleum and chemical pipe insulation projects

- Calorifer and heating networks

- Central air conditioning ventilation pipes

- Municipal projects (urban engineering)

- In geothermal heating and cooling systems

- Liquid and gas transmission pipe facilities

- Central heating pipes

- Fire systems

- Industry pipelines

- Greenhouse systems

- Hotels and tourism installation lines

- Military organisations

- Ship and marine vessel piping systems

- Mass housing developments

- Universities and colleges

- Cogeneration

- Various Cooling Lines

General features and advantages of Pre-Insulated (Geothermal) Steel Pipes

- Geothermal steel pipes pass through the fabrication production stage.

- Pre-Insulated Steel Pipe can be categorised as composite pipe as it consists of different material layers.

- Site and district heating pipes in accordance with the standards.

- They maintain the temperature/coldness of the transported fluid.

- They can also be used in geothermal water heating and central heat plants.

- If standard production is made, the carrier pipe is made of steel.

- The steel pipe is resistant up to 140 ºC water temperature.

- Polyurethane material used as insulation material is produced in accordance with TS EN 253 standards.

- The insulation material does not absorb water thanks to its gated cell structure.

- The insulation coefficient of the insulation material used is higher than glass wool-like materials.

- Since the polyurethane sheath forms a chemical bond with the pipe thanks to the corona application, it acts as a single structure in the thermal expansion event. Therefore, the carrier pipe does not elongate and the insulation is not damaged.

- Thermal conductivity is 0.029 W/(mK).

- The density of foam, which is a thermal insulation material, is minimum 60 kg/m3.

- It can operate continuously with fluids up to 120 ˚C. The temperature value of the fluid can rise up to 140 ˚C.

- Since heat bridges are not formed during assembly, heat loss is at minimum level.

- There is no leakage thanks to the sliding sheaths that can be used at the joints of the heat insulated pipe. The use of this system also prevents deterioration of the insulation.

- L, Z, U bends are not used in pre-stressed systems where laying operations that do not require channel widening are performed.

- Operating cost remains constant throughout the insulation life. There is no maintenance cost.

- Installation is simple.

- Time and labour saving is high.

- Workmanship errors are minimised.

- No gallery is required during laying. The pipe is buried in the soil. Construction cost is low.

- Tensile resistance of the casing pipe provides safety up to -50 degrees.

- It has a minimum life of 30 years in accordance with TS EN 253 standards.

- Compensator usage is low. Elongation element is used at minimum level.

- It has equal and homogenous insulation thickness at every point.

- It has 40% energy saving compared to classical insulation techniques.

- It is resistant to chemicals and sun rays.

How are pre-insulated (Geothermal) pipes manufactured?

Geothermal steel pipes are prepared by the company in their own production areas as monolithic. If a steel pipe is to be used as a carrier pipe, it will be supplied from another manufacturer and sequential processes will be carried out. If desired, epoxy paint can be applied inside and on the outer surface of the steel pipe. If PPr pipe will be used as the carrier pipe, PPr pipe is subjected to an extrusion process which is a shaping process. After this process, mass production can be started. In the upper region of the PPr pipe, which is made of random copolymer polypropylene material, axial parts are placed. Then the leakage sensor wires are positioned. Polyethylene (PE) pipe is passed over the inserted parts after the axing process. In the area between the carrier pipe and the outer sheath pipe, the mouth part is closed for pressing polyurethane material.

Holes are placed on the heat-insulated pipe to ensure pur pressing. Polyol and isocyanate fluids forming the PUR to be used for insulation are mixed with the machine. Then the mixture is pressed between the carrier pipe and the outer casing pipe. Polyol and isocyanate liquids that react by mixing swell and expand. Polyurethane Foam insulation material gains a heat-proof feature thanks to its pores. With the solidification of PUR, the geothermal pipe manufacturing process is completed. Steel pipe or PPr pipe can be used in production. The outermost sheath pipe, which must be resistant to the pressure created by the polyurethane foam material, must have dimensions to meet the standards. TS EN 253 norms should be taken into consideration in the production of casing pipe.

Considerations when installing pre-insulated geothermal steel pipes

During installation, utmost care must be taken to prevent damage to the sensor wires placed in PUR.

When joining the ends of the inserted cable to each other, it must be done very firmly.

When using shrinkable polyethylene tapes in the spliced parts, heating should be done in such a way that there are no gaps. If this issue is not taken into consideration, the remaining gaps will cause the insulation material to get wet and eventually deteriorate.

In order to prevent the Solid Polyurethane (PUR) Insulation, which is the insulation material, from being adversely affected by the sparks that may arise during the welding of the steel pipe to be used as the carrier pipe, the material should be placed in the intermediate area to prevent the sparks from reaching the insulation.

During the stock operations of heat-insulated steel pipes, the outside parts of the Solid Polyurethane (PUR) Insulation material should be closed in order not to be adversely affected by natural events (rain, snow, moisture).

While laying the heat-insulated geothermal pipe under the ground, the channel-filling process is also carried out. During this process, there should be no gaps around the pipes. Layer compaction can be done for this.

It is also important to fill the bottom of the heat-insulated pipe with filling material, and if this process is not performed, a gap remains in the surface section. Since compression is not provided, friction forces will remain low and will cause the pipe to elongate more. Since this system is a pre-stressed system, no compensator is used. For this reason, the filling process is one of the most important stages of the installation part of the project.

Rigid Polyurethane Foam PUR must adhere very well to the transport pipe and the casing pipe. This must be checked in detail. If the PUR does not adhere to the transport pipe and casing pipe, the soil friction force will have no effect to prevent elongation.

Company production areas with only foam pressing machines may be insufficient. If there is harmonious work between the units, the space is thrown out during the swelling of the polyurethane foam and the insulation is provided in a good way. If there is a gap inside, soil collapse may occur on the laid areas.

What are the contributions of pre-insulated geothermal steel pipes to environmental protection?

Rapidly increasing carbon emission is an environmental problem that all countries of the world are struggling with. Every sector has to take the necessary measures in its production. In addition to the measures taken in the production of pre-insulated steel pipes, the use of these products has many benefits to the environment. Some of these are:

Pre-insulated steel pipes provide high energy savings by reducing the heat loss of the fluids they transport. It contributes to the reduction of energy consumption by minimizing the energy loss of hot or cold fluids passing through specially designed pre-insulated pipes. Reducing energy consumption means less fuel consumption and less greenhouse gas emissions.

Since the use of geothermal steel pipes reduces energy loss, it also plays a role in reducing the amount of waste generated in energy production. Reducing the amount of waste means keeping the air, soil and water resources cleaner.

Due to the reduction of energy consumption, it reduces the emission of greenhouse gases on the line where pre-insulated steel pipes are used. In this way, it contributes to the reduction of carbon footprint in the region where the pipeline is used.

Pre-insulated steel pipes are produced from recyclable materials. Recycling pipes that have completed their useful life contributes to reducing environmental pollution.

Pre-insulated steel pipes play an important role in terms of environmental safety and health, depending on the characteristics of the transported fluid. It reduces the risks of burning and explosion in the transportation of flammable and explosive fluids.

The energy saving provided by the pre-heat insulated steel pipes contributes to the sustainability of energy resources.

The use of pre-insulated steel pipes contributes to the protection of air, soil and water resources with their environmentalist properties. Pre-insulated geothermal steel pipes have exemplary environmentalism, thanks to their energy saving, waste reduction, sustainability of energy resources, environmental safety and high recyclability.

Frequently Asked Questions

How long will the pre-insulated geothermal pipe last?

Pre-insulated pipes, also known as geothermal pipes, package pipes or pre-insulated pipes in the sector, have an insulation life of 30 years at a permanent operating temperature of 120 ° C, 50 years at a permanent operating temperature of 115 ° C and more than 50 years at temperatures below 115 ° C when they are made of TS EN 253 norms.

Up to what temperature can pre-insulated steel pipes be used?

Pre-insulated steel pipes can be used for transports with a liquid temperature of up to 140°C.

Can pre-insulated steel pipes be used at temperatures above 140 °C?

If the fluid temperature to be transported is above 140°C, the transport is provided by using Rockwool-PUR mixture material in the insulation section of the pre-heat insulated steel pipe.

Can geothermal pipes be used for steam transport?

Steam transport service can also be provided with systems where steel pipes are used as carrier pipes.

Is it possible to use pre-heat insulated geothermal steel pipes in cold water lines?

The main feature of pre-insulated pipes is to prevent heat loss and transfer both from inside to outside and from outside to inside. In cold fluid transports, it is also important to prevent the transfer of heat from outside to inside. For this reason, cooled fluids can also be transported by retaining their heat with heat-insulated steel pipes that have a complete insulation feature.

Are compensators used in heat-insulated pipes?

Due to the laying feature of pre-heat insulated pipes, pipe elongation in the inner region is prevented with the help of soil friction forces, so there is no elongation as in other pipe systems. For this reason, in pre-insulated pipes, compensators produced to prevent dimensional change and eliminate the problems caused by heat-related expansion and contraction in the pipeline are not used.

Is corona treatment necessary for pre-heat insulated steel pipes?

When laying pre-heat insulated pipes, soil friction forces are utilized to prevent pipe elongation. For this process, solid polyurethane insulation material (PUR) must react chemically with both steel pipe and polyethylene sheath pipe and form a bond. If the corona is not made in heat-insulated pipes, a compensator is used.

Is the gallery opened when laying pre-insulated pipes?

Since the pre-insulated steel pipe system is buried in the subsoil layer, the laying process is carried out without opening a gallery. In case of opening a gallery, the process should be continued considering the pipe elongation.