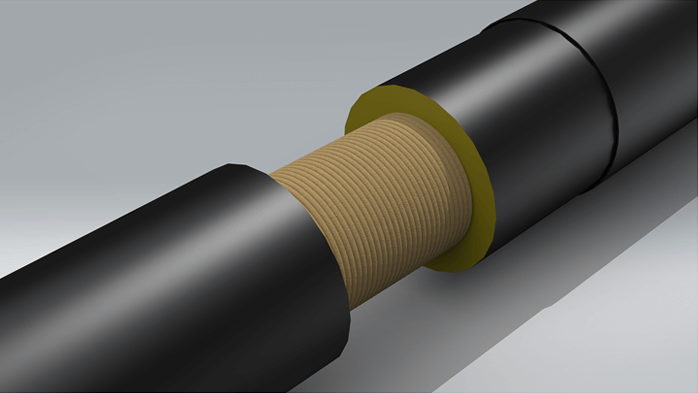

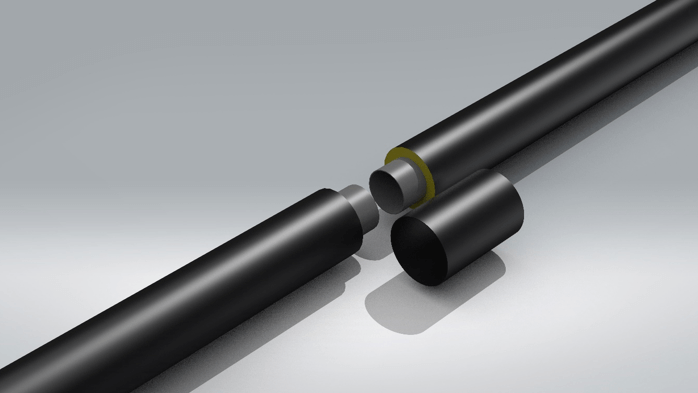

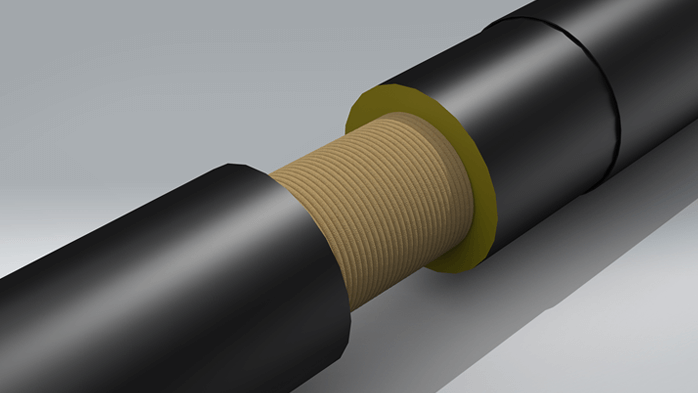

In pre-insulated pipe systems, there are uninsulated parts at the pipe ends so that the installation and welding processes of the pipes can be carried out, and after the welding is done, joint insulation kits are used for fulfilling the insulation of these parts.

Proper application is important for the protection of the carrier pipe from impacts such as corrosion etc. and provision of the insulation homogeneously throughout the system. In order to ensure that this application is easy and trouble-free for the customers, an application instruction manual and the prescriptions in which the quantity of materials required for each kit are supplied along with the products

The materials included with the insulation kit are:

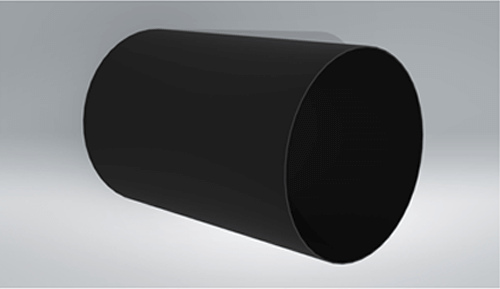

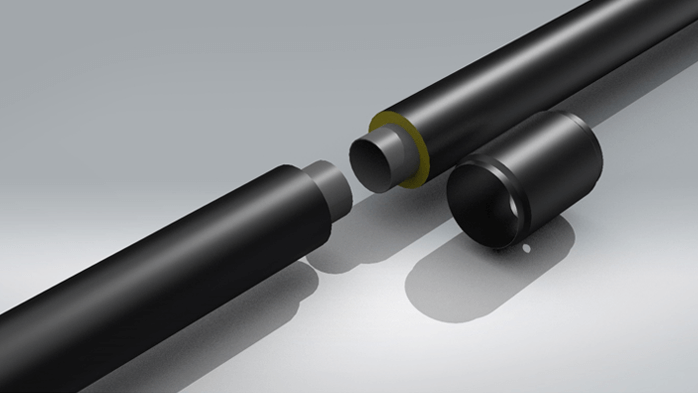

HDPE CASING PIPE

HDPE CASING PIPE

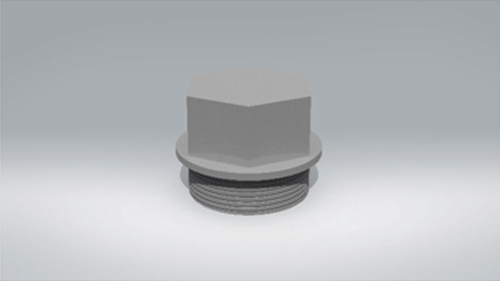

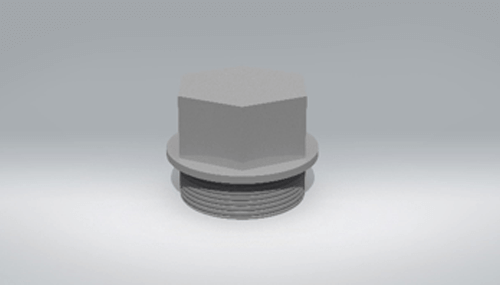

PLUG

PLUG

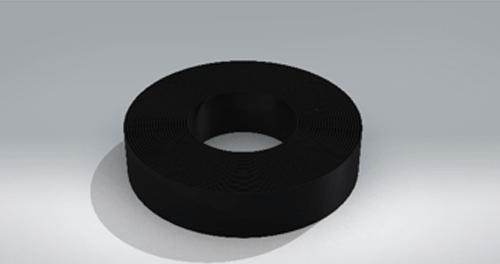

HEAT-SHRINK

HEAT-SHRINK

POLYOL

POLYOL

ISOCYANATE

ISOCYANATE

Application:

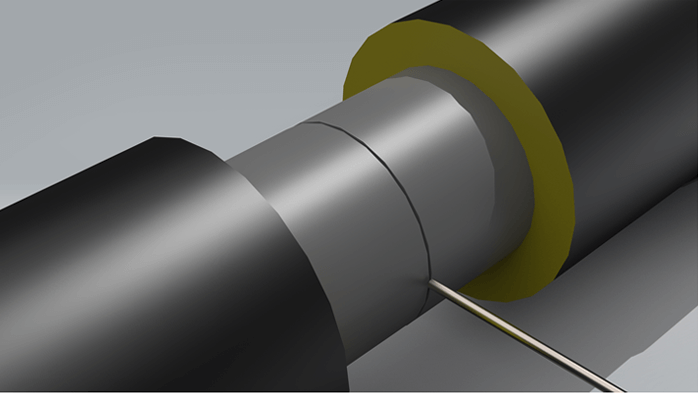

- Before the installation and welding of the pipes, the HDPE casing pipe must be put on around the pipes.

- The uninsulated parts of approximately 15 - 20 cm on the carrier pipes must be totally free of dirt and moisture. The welding of the pipes of which the HDPE casing pipes are installed and which are cleaned is performed.

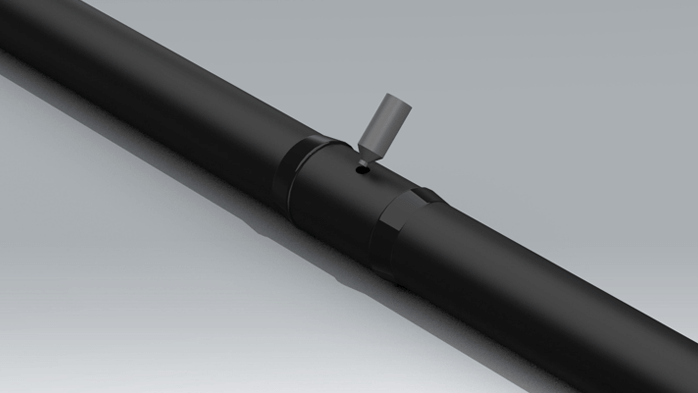

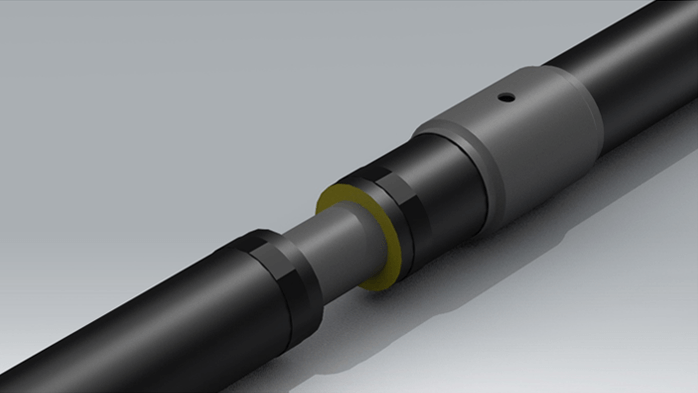

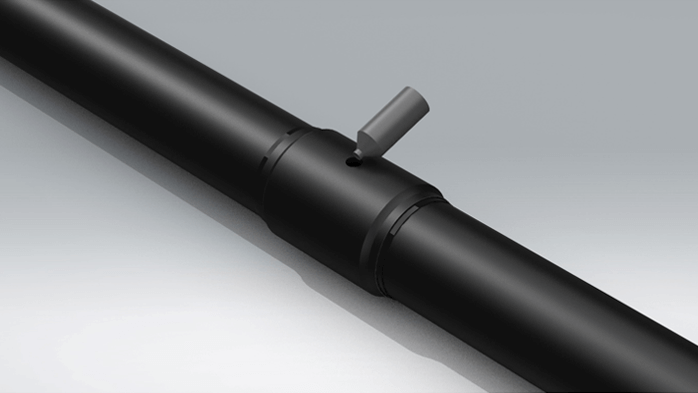

- The HDPE casing pipe must be placed in the middle of the non-insulated part as shown in the figure below, and care must be taken to ensure that the hole through which the insulation material will be poured remains at the top.

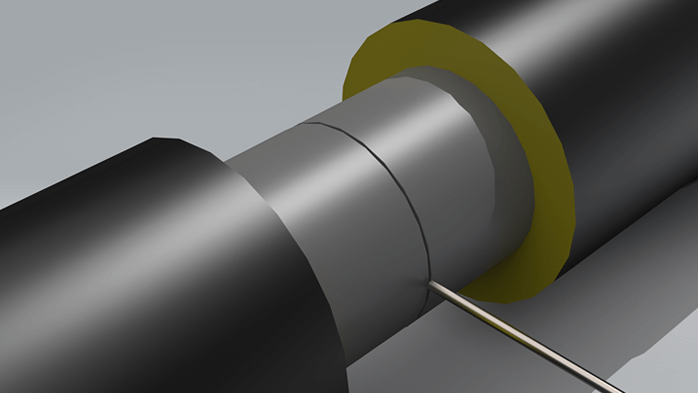

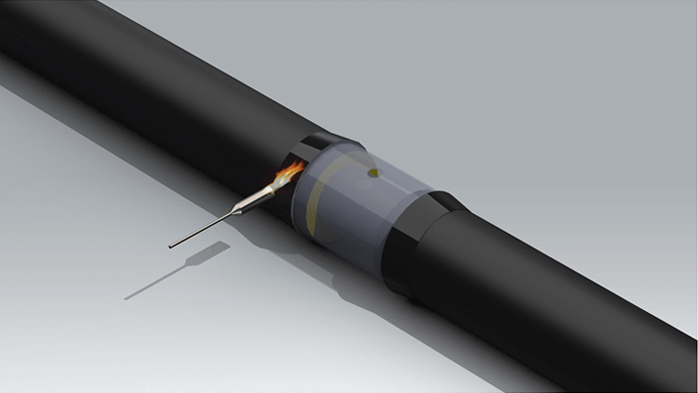

- Heat-shrink tapes are adhered by wrapping one turn in the middle of the HDPE casing pipe and the main pipe as shown below.

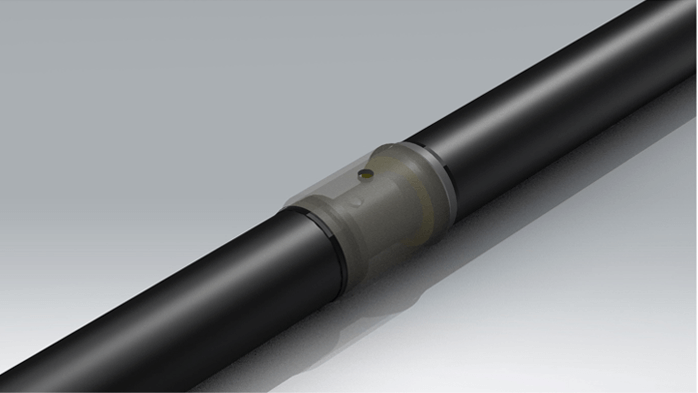

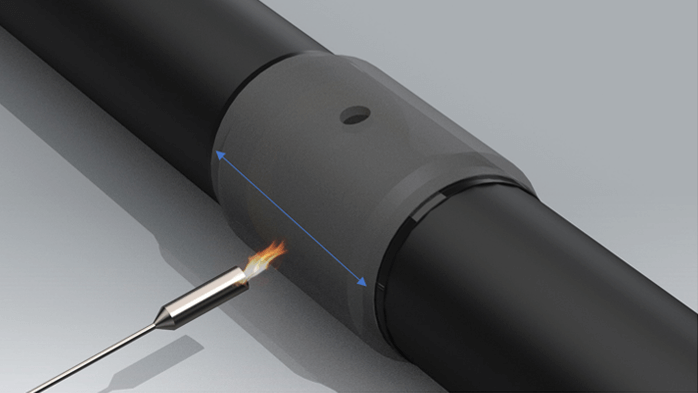

- Heat-shrink tapes are heated with a blowtorch and adhered to the casing pipe. In order to avoid air bubbles under the tapes and to ensure complete adhesion, the tapes can be pressed with the help of heat-proof gloves. During heating, the blowtorch must not be kept at the same point; heating must be done by moving the blowtorch around the tape. After the procedure, it is sufficient to wait 5-10 minutes for the tape to cool down.

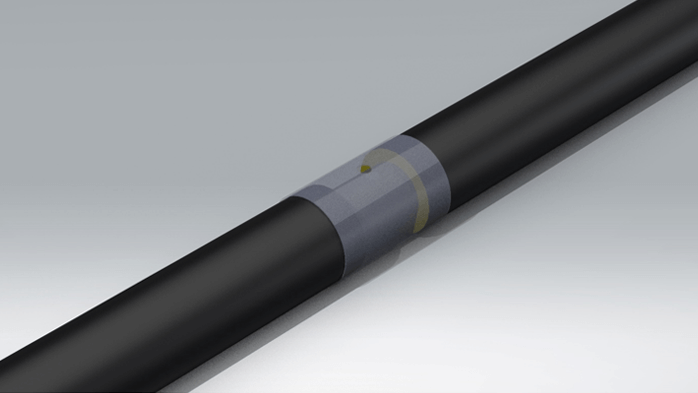

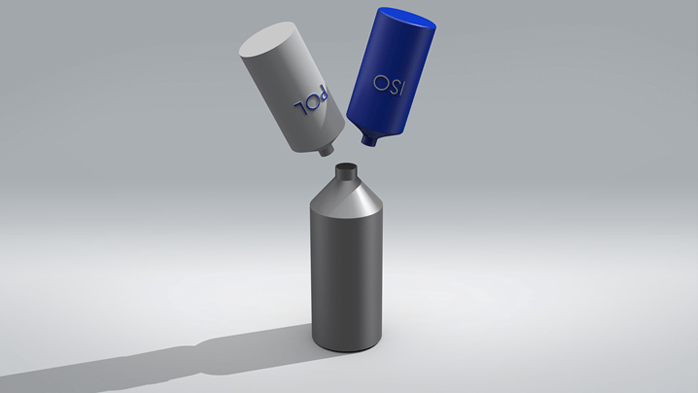

- After adhesion, the POL and ISO in the quantities of mixture as prescribed in the consumables chart provided by Yalçın Boru are put in a container and they are mixed.

- The insulation material mixed in the container is poured through the hole, and it must be waited until the air is released. After the mixture is prepared in the container, pouring through the hole must be completed quickly (within 5-10 seconds). Polyol and isocyanate can get into reaction within a very short time and it can expand very fast.

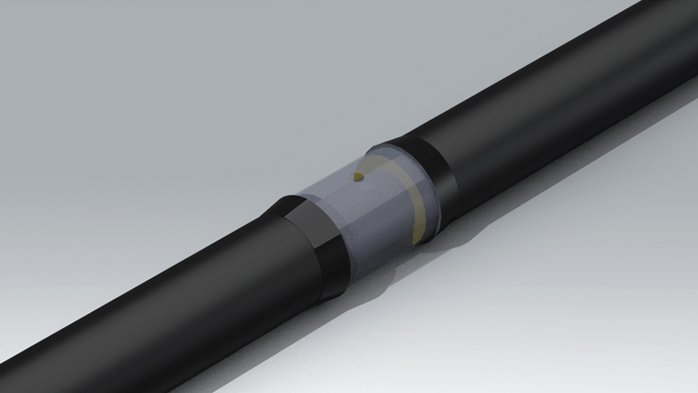

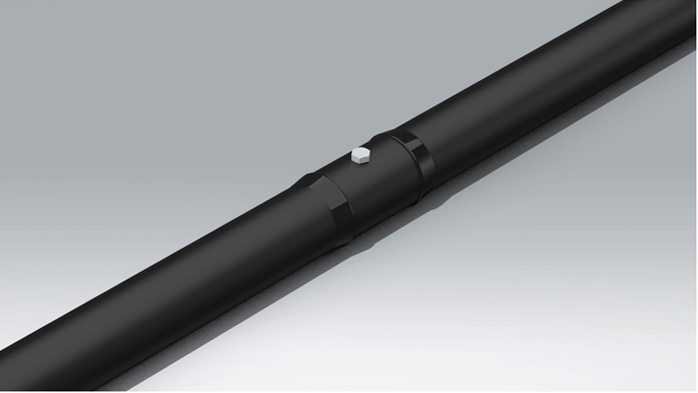

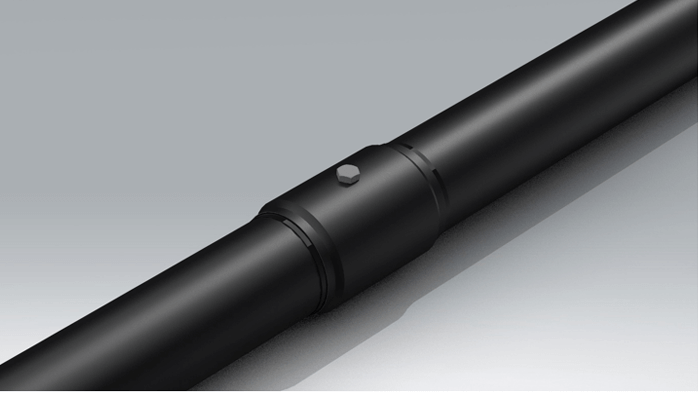

- Air release is observed through the hole on the HDPE casing pipe, and when it is ensured that it is completely filled, the plug included in the kit is hammered into the hole and the joint insulation process is completed.

Application of Joint Insulation Kit on Industrial Type (Rockwool Reinforced) Pre-insulated Pipes

The joint insulation kits of this product, which is used for steam installations, contain rock wool (pipe type or blanket type) and it must be wrapped around the uninsulated parts at the pipe ends. This process must be performed before the casing pipe is adhered with heat-shrink tapes, and then the steps provided in the instruction manual must be followed in the same order.

In pre-insulated pipe systems, there are uninsulated parts at the pipe ends so that the installation and welding processes of the pipes can be carried out, and after the welding is done, joint insulation kits are used for fulfilling the insulation of these parts.

Proper application is important for the protection of the carrier pipe from impacts such as corrosion etc. and provision of the insulation homogeneously throughout the system. In order to ensure that this application is easy and trouble-free for the customers, an application instruction manual and the prescriptions in which the quantity of materials required for each kit are supplied along with the products.

The materials included with the insulation kit are:

COMPLETE HEAT-SHRINK JOINT

COMPLETE HEAT-SHRINK JOINT

PLUG

PLUG

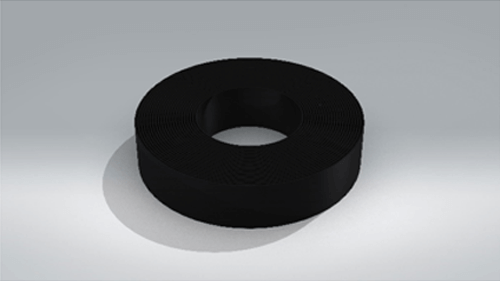

ADHESIVE TAPE

ADHESIVE TAPE

POLYOL

POLYOL

ISOCYANATE

ISOCYANATE

Application :

- Before the installation and welding of the pipes, the JOINT must be put on around the pipes.

- The uninsulated parts of approximately 15 - 20 cm on the carrier pipes must be totally free of dirt and moisture. The welding of the pipes of which the HDPE casing pipes are installed and which are cleaned is performed.

- Adhesive tapes must be wrapped around the parts where the joint will coincide on the pipe. For a more suitable adhesion, the parts to be wrapped with the adhesive tape must be cleaned. Afterwards, the adhesive tapes must be heated by means of a blowtorch and the adhesive layer that will form on the tape surface must be observed.

- After the process of heating the adhesive tape, the joint process must be placed at the centre of the uninsulated part. It must be noted that the hole on the joint remains at the top.

- Complete heat-shrink joint is started being heated with a blowtorch. Due to its structure, the joint shrinks with heat and takes a shape suitable for the diameter of the casing pipe on which it is applied. During the heating process, the blowtorch must not be kept at a constant point on the joint, and a homogeneous heating and shrinking process must be carried out by circulating it around.

- After adhesion, the POL and ISO in the quantities of mixture as prescribed in the consumables chart provided by Yalçın Boru are put in a container and they are mixed.

- The insulation material mixed in the container is poured through the hole, and it must be waited until the air is released. After the mixture is prepared in the container, pouring through the hole must be completed quickly (within 5-10 seconds). Polyol and isocyanate can get into reaction within a very short time and it can expand very fast.

- Air release is observed through the hole on the Joint, and when it is ensured that it is completely filled, the plug included in the kit is hammered into the hole and the joint insulation process is completed.

Application of Joint Insulation Kit on Industrial Type (Rockwool Reinforced) Pre-insulated Pipes

The joint insulation kits of this product, which is used for steam installations, contain rock wool (pipe type or blanket type) and it must be wrapped around the uninsulated parts at the pipe ends. This process must be performed after the welding process, and then the steps provided in the instruction manual must be followed in the same order.